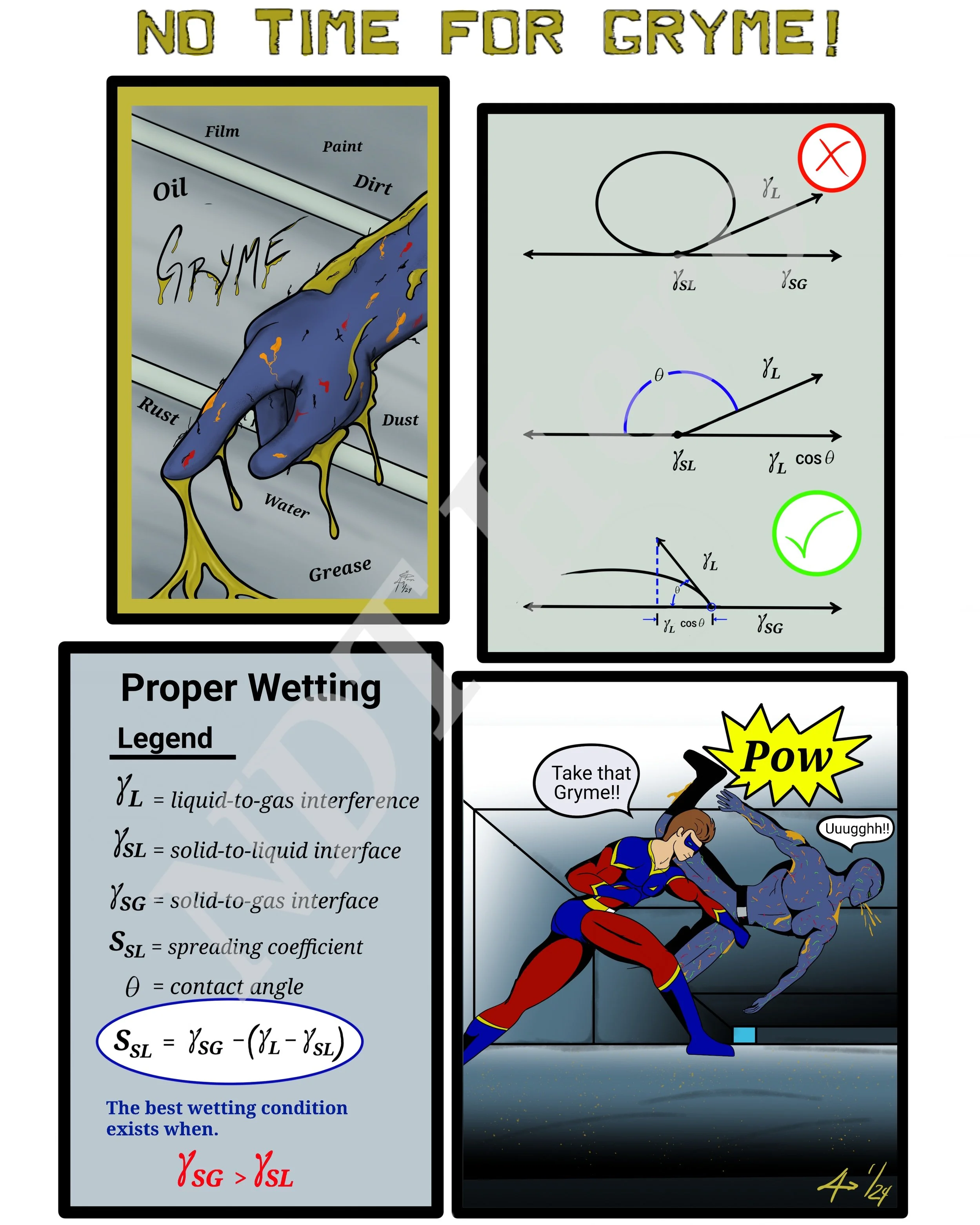

Angles Matter

When it comes to performing Liquid Penetrant Testing (PT) it is important to observe the fluid flow across the surface of the test object to insure it is wetting effectively. When the contact angle is 90 degrees or greater we have a problem with the part surface of penetrant materials that requires another look

“Fractureman” is looking for an opportunity to create havoc beneath the scenes. Improper fluid contact angle can prevent proper penetration into open surface indications like (cracks, seams, laps) that shorten the life of the part and poses potential danger to the public.

The cause for poor contact angle is typically a residual film left on the test object surface. This film may be oil, grease, release agents, or other coating placed on the part during a previous process.

In cases where the penetrant is not wetting correctly over the surface or parts of the test object surface the penetrant must be removed, part cleaned, and penetrant re-applied.

The sign of for wetting begins the moment liquid penetrant contacts the part surface and the liquid forms into small spheres accross the surface. This is a good look for a sports car but not for a liquid penetrant test.

The formula for success lies in performing a thorough pre-clean with the penetrant manufacturers solvent.

The actual formula for calculating the ”Contact Angle” is here for your calculations on your way to knocking Gryne off his feet and out the door.