No Room for Grime

Grime comes in many forms. None of which add any value to a quality inspection.

Dirt, oil, grease, weld spatter are all “Gryme” aka NDT Hero villian weapons designed to negatively affect NDT results. Today we will focus on weld spatter and how it impacts different NDT methods.

WELD SPATTER

Weld spatter is caused by many factors and is often seen as poor workmanship. Some spatter is acceptable but good workmanship means knocking these little molten metal drops off with a hammer or grinder before turning it in for final inspection.

PT - Where there is spatter there is poor cleanliness which leads to false calls and additional time having to re-evaluate suspicious bleed out. The penetrant gets trapped in the crevices and steep edges of the spatter.

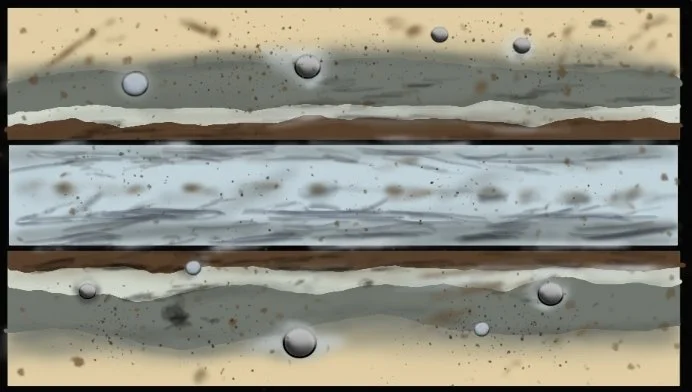

MT - Similar results happen with MT, as seen with color contrast here.

RT - Radiographicaly the spatter is obvious and shows poor workmanship which is often cause for rejection.

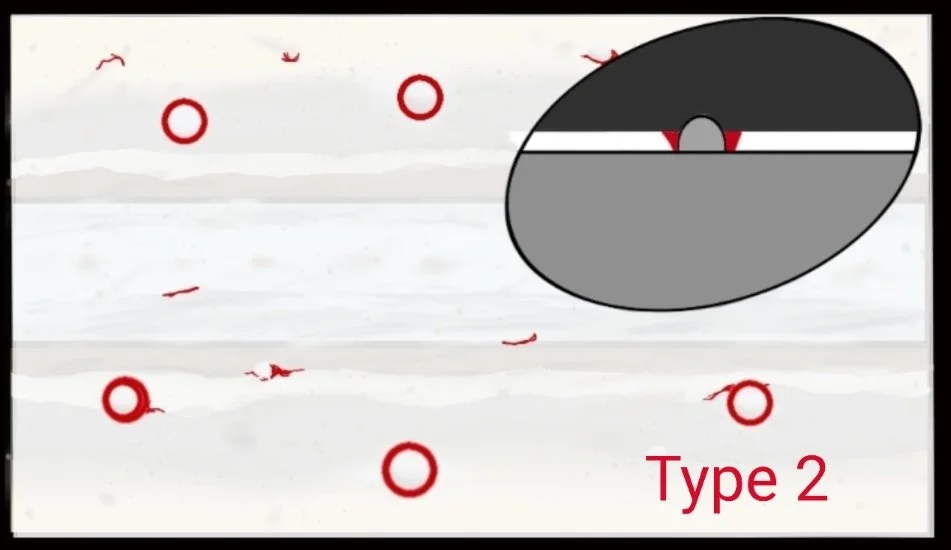

UT - The problem we face when performing UT is probe manipulation, or lack there of.